Advantages

Experience – With over two decades of experience producing mouse monoclonal antibodies, GMAb has worked with all types of antigens and complex screening parameters. We aim to produce specific monoclonal antibodies rapidly and with high affinity. We have optimized our protocols with this goal in mind.

Time Savings – Our rapid protocol and collaborative data review process allows us to move seamlessly through each phase and make real time decisions to meet the needs of the project. To avoid processing the cells through a thaw cycle, we discuss fusion and subcloning screening data the same day. This saves weeks in your hybridoma development process.

Superior Service – A single project manager will coordinate all aspects of your experience and help you refine the scope and design of your project to achieve your goals.

Flexibility – GMAb is always open to discussing new ideas and protocols. We enjoy learning from our customers and always welcome the opportunity to brainstorm.

The Green Mountain Experience

Program discussion: Green Mountain Antibodies wants to understand your project, the target, end application, and timeline goals. The more we know, the better we can strategize. To start the discussion, please contact us at sales@greenmoab.com to review our CDA or download an Initiation form and send it to sales@greenmoab.com.

Antigen Design: Whether the reagents are available or input on peptide design or protein production is required, selection of the immunizing antigen will be guided by our experienced science team.

Project Plan: First we will discuss the project in detail. Then we will provide a Project Plan and budget for your approval.

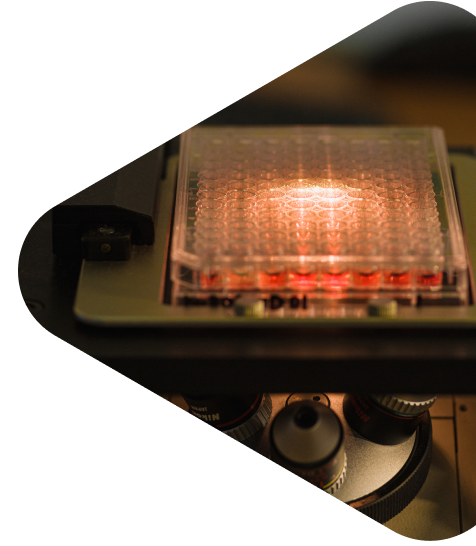

Hybridoma Development and Assay Services: We add the project to the schedule when the signed Project Plan, reagents, and PO are in-house. Our goal is to start projects within a week or less of receiving material. Immunizations, fusion, and subcloning can take 3 to 4 months. If your project can benefit from flow cytometry, the service can be incorporated into a screening at each phase. Additional characterization of the antibodies can be done once purified material is available. We share all data online via ShareFile. This provides easy and on-demand access. Cells remain in culture throughout the process to avoid delay and freeze/thaw cycles.

Antibody Production, Purification, and Assay Services: Milligram to gram quantities can be produced via in vitro methods. This adds 4 to 6 weeks to the timeline. The antibodies can be tested by size exclusion chromatography (SEC), dynamic light scattering, isotype, isoelectric focusing, SDS-polyacrylamide gel electrophoresis (PAGE), antibody sequencing, and Gator analysis.